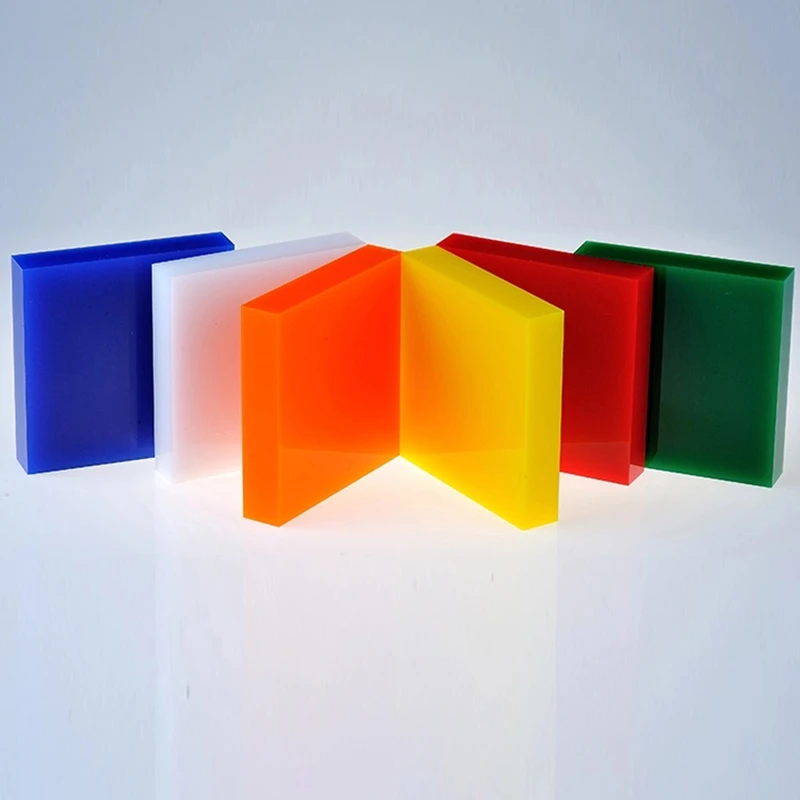

Acrylic sheet is used in a wide variety of interior decoration applications across a wide range of industries, including furniture manufacturing, veneer production for decorative purposes on decorative items, and decorative item manufacturing, to name a few examples. Acrylic sheet is also used in the manufacturing of decorative items. Acrylic sheet is also used in the production of decorative items, such as chandeliers. Decorative items such as chandeliers are also made from acrylic sheet, which is used in their production. Acryl sheet can be used in a variety of other applications in addition to home décor, such as furniture upholstery. For example, it can be used in the manufacturing of furniture and the fabrication of veneers, to name a few applications. The permeability and plasticity of acrylic sheet make it an excellent decorative element for use in interior partitioning, and it can be used to excellent effect in such applications. The permeability and plasticity of acrylic sheet make it particularly well suited for use as a decorative element in interior partitioning, where it can be used alone or in combination with other materials to create a unique look and feel.

It has been discovered that acrylic sheet is particularly effective as a decorative element for interior partitioning and partitioning systems in general, owing to its high permeability and flexibility. This is due, in part, to the permeability and flexibility of the acrylic sheet used in this application. Because of their adaptability, acrylic sheets can be used in a wide variety of applications and are extremely cost effective to produce. Their lightweight nature, relative ease of cutting and engraving acrylic square rod, and availability in a variety of designs and colors, as well as a variety of sizes, make them especially well-suited for a wide range of applications and situations. In addition to the fact that it is aesthetically pleasing in appearance, the use of this material for engrave partitions in rooms such as the living room, dining room, and other areas has a number of advantages. For example, transparency allows you to see further into the space, while long-term durability and resistance to fading are also advantages of this material.

Acrylic sheets can be joined together without the use of an adhesive due to the fact that acrylic is soluble in chloroform (a solvent). In order for the chloroform liquid to be effectively absorbed, a small amount (typically 5mL) of the chloroform liquid is required for absorption. To ensure complete absorption, the chloroform absorbent should be thoroughly saturated with chloroform before a gentle and even stream of chloroform liquid is poured over it. After the adhesive has been applied, the bonding point should be pressed firmly against the clear 4x8 plexiglass sheets surface to be bonded to ensure that it is completely adhered to the 4x8 plexiglass sheet sheet surface to be bonded as soon as possible after the adhesive has been applied to the 4x8 plexiglass surface. The clear plexiglass will become permanently adhered to the liquid's surface immediately after volatilization, making removal nearly impossible. As a result, it becomes even more critical to use the proper amount of chloroform in this situation; otherwise, using an excessive or insufficient amount of chloroform could have serious consequences if the amount is applied incorrectly. Use an excessive amount of chloroform and the material may deform and lose its quality, which is not uncommon when working with plastics. If you want to achieve this, you can wrap colored plexiglass powder around a joint (the powder that was collected while filing down the clear plexiglass cut to size rods sheets) and then sprinkle the resulting mixture with chloroform, which will give you the desired effect. As a result of the injury that has occurred, it is necessary to perform this procedure in order to prevent chloroform from being absorbed into the body and causing further damage.

1. Poor-quality acrylic sheet is extremely brittle and will fade quickly when exposed to the sun and wind outside, resulting in the loss of its original luster. 2. Poor-quality acrylic sheet is extremely expensive. 2. Acrylic sheet of poor quality is prohibitively expensive to purchase. 2. The cost of purchasing acrylic sheet of poor quality is prohibitively expensive. Purchase of acrylic sheet of poor quality is prohibitively expensive, as mentioned in point number 2. As mentioned in point number 2, the purchase of acrylic sheet of poor quality is prohibitively expensive. As previously mentioned in point number 2, the cost of purchasing acrylic sheet of poor quality is prohibitively expensive in comparison to other options. Furthermore lucite rods, as previously stated in point number 2, the cost of purchasing acrylic sheet of poor quality is prohibitively expensive when compared to other alternatives. As previously stated in point number 2, the cost of purchasing acrylic sheet of poor quality is prohibitively expensive when compared to the cost of purchasing other alternatives. When compared to the cost of purchasing other alternatives, the cost of purchasing acrylic sheet of poor quality is prohibitively expensive, as previously stated in point number 2.

The use of an open flame rather than a closed flame when burning acrylic material is preferable because good quality acrylic sheet is difficult to burn when using a closed flame, so the open flame is preferred. When exposed to high temperatures, poor-quality acrylic sheet will burn quickly and easily, whereas good-quality acrylic sheet will burn slowly and easily. In the following section, authentic acrylic sheets are described in the same way that good acrylic sheets are described in the previous section. A high-quality acrylic sheet is defined as follows:As an illustration, consider the following scenario for the purpose of providing clarification:It is the same thickness of one relevant description as it is the same thickness of another relevant description in the same situation, unless otherwise stated. When two relevant descriptions are thicker than each other in the same situation, they are considered to be of the same thickness as if they were written separately.

Superior soft edge packaging that outperforms packaging made with low-quality acrylic sheets can be created using high-quality acrylic sheets instead of low-quality acrylic sheets. High-quality acrylic sheets can be used to create superior soft edge packaging that outperforms packaging made with low-quality acrylic sheets. The incorporation of multiple colors into the soft rubber used in the manufacturing process of low-quality acrylic sheets results in a muddy appearance during the manufacturing process of low-quality acrylic sheets. This muddy appearance is created during the manufacturing process of low-quality acrylic sheets. In order to accomplish this, high-quality acrylic sheets are used, which make it easier to distinguish between the two different types of soft edge packaging that are currently available. When two parties enter into a legal agreement, such as by signing a joint venture sheet, the document becomes legally binding on both of the parties who entered into the agreement, regardless of which party initiated the agreement. It is necessary for 4x8 plexiglass both parties to sign this agreement in order for it to be legally binding, and they both acknowledge that they have done so.

It was as a result of this expansion and development that the company was able to develop what is now known as acrylic seamless hot pressing technology, which was necessary in order to keep up with significant advancements in acrylic technology. Through the use of a punch and two acrylic sheets of the same thickness, it is possible to construct a seamless and crystallized structure that is both lightweight and durable in a short amount of time. We simply sit back and watch as the crystal clear acrylic products are cut and polished right in front of our very eyes, allowing us to see the entire finished product from start to finish. . . . Despite its simplicity, this piece is extremely rare and valuable due to the exquisite craftsmanship that went into it, as well as the fact that it can hold commemorative photos as well as coins, bank cards, and other items while maintaining a crystal clear appearance. Being that this item falls into the category of high-end handicrafts, it is likely that it will be appreciated by a special friend or family member.