Rubber vulcanization temperature is the basic condition for rubber vulcanization reaction (crosslinking reaction), which directly affects the speed of microwave curing oven and the quality of products. As with all chemical reactions, the vulcanization reaction accelerates with increasing temperature, and it is easy to form more low-sulfur crosslinks. If the vulcanization temperature is low, the speed is slow, the efficiency is low, and more polysulfide crosslinks are formed. The vulcanization temperature is generally applicable to Vanthofer's law, that is, the reaction rate doubles every time the temperature rises by 8 to 10 ° C (about the vapor pressure of a gauge pressure); or the reaction time is reduced by about half.

With the increase of room temperature vulcanizate and the emergence of high temperature vulcanization, the vulcanization temperature tends to two extremes. From the perspective of improving the curing efficiency, it should be considered that the higher the curing temperature, the better, but in reality, the curing temperature cannot be increased infinitely. Rubber is a high-molecular polymer. High temperature will cause a cracking reaction of the rubber molecular chain, which will cause the cross-linking bond to break, that is, the phenomenon of "vulcanization back to original" will occur, thereby reducing the physical and mechanical properties of the vulcanizate. For example, when vulcanizing natural rubber at high temperature, the oxygen dissolved in the rubber increases in activity as the temperature increases, causing strong oxidation, destroying the rubber structure, and reducing the physical and mechanical properties of the vulcanizate.

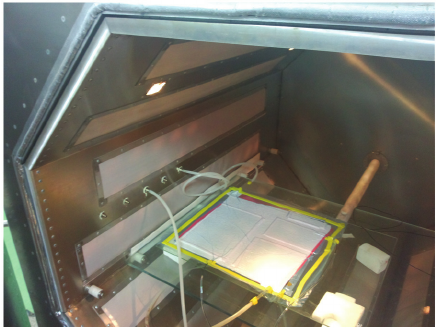

Heating Equipment Of Microwave Curing Oven