Digital 3D technologies have a huge impact on the automotive industry. In the sector, where technological innovations are caused by the constant desire to remain competitive. Due to the huge advantages of 3D printing from the point of view of economic and production sustainability, its development will lead to changes in the coming years.

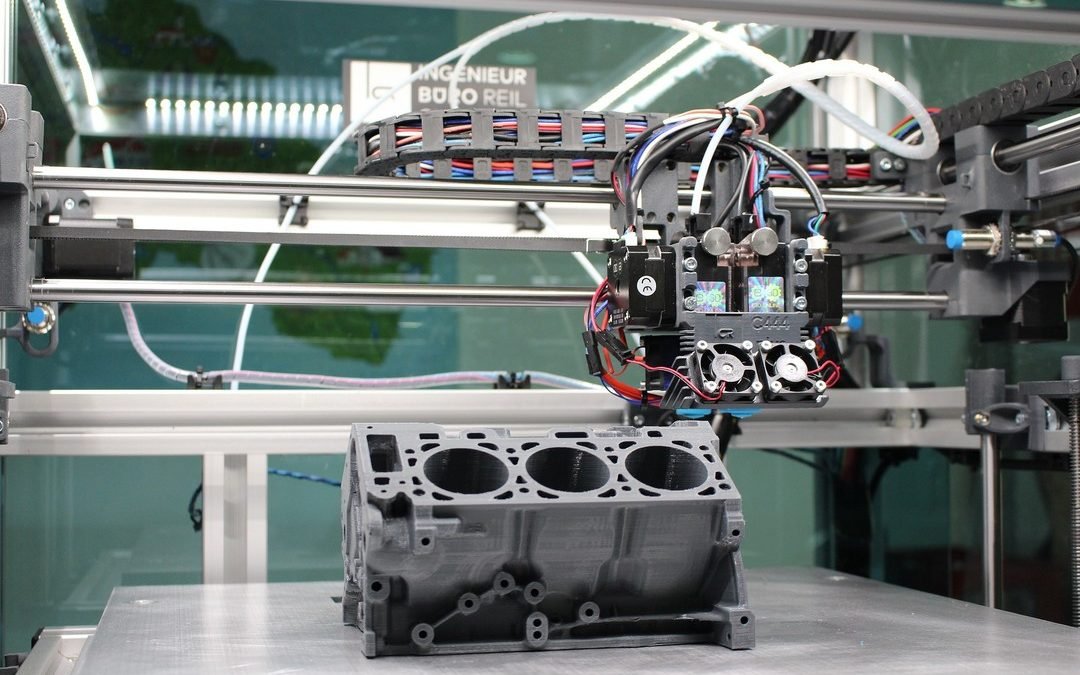

In the technology of free molding "Fused Deposition Modeling" (FDM), three-dimensional printing, which originated in the late 1980s, is becoming more and more popular. In fact, Ford has been using this technology since the design stage of cars, as it is a fast and efficient way to physically deploy components before final production.

In 2005, Professor Adrian Brauer initiated the RepRap project - a worldwide movement for self-replication of 3D printers using open source software, which brought the FDM company closer to the consumer world and created new research perspectives for engineers.

Using traditional modeling methods, an engineer designing car parts on a computer has to wait several months to build a prototype. At the same time, 3D printing reduces the waiting time, to such an extent that each part will be available within a few days or just a few hours. You can even get a prototype of a whole car on a scale of 1:1 at a much lower price.

THERMOPLASTS IN 3D PRINTING

The specifications of the parts are transferred from the design program to the printer's computer, which prints one layer of material at a time, gradually folding them together to form a complete 3D object. Thermoplastics, such as polypropylene (PP), are an ideal material for 3D printing and, therefore, an indispensable tool in the automotive industry's weight reduction strategy.

Polypropylene is the most commonly used plastic in the production of cars due to its weight, wear resistance and ability to absorb shocks, as well as strength and flexibility. To use all its advantages, some manufacturers of 3D printers have developed polypropylene derivatives similar to propylene to strengthen its physical and mechanical properties.

3D technology in the automotive industry continues to develop.

3D technology is developing in the automotive industry. The report "Future Outlook of the Automotive 3D Printing Market" and "Rapid Technological Advances" by Acumen Research and Consulting (ARC) predicts the automotive 3D printing market to grow at a CAGR of 24.6% (compound annual growth rate) by 2026, when it will amount to 3.9 billion dollars.

3D printing allows you to work more efficiently with more personalized designs adapted to your needs, and to test different versions of the product faster and cheaper.

MORE LIGHT AND PERSONALIZED CARS

Major automotive brands, such as Volkswagen, BMW, Jaguar or Land Rover, use 3D technology to reduce the weight of their cars and production costs. In 2015, Audi 3D-printed the design to avoid having to manufacture and ship certain parts around the world. Printing on demand excludes the serial production of certain components, which allows you to save on infrastructure maintenance costs. This also applies to the production of spare parts.

The development of 3D technology affects how companies treat their customers. Twikit personalization software from MINI gives buyers full control over the design of their cars. They can customize elements both indoors and outdoors using a wide range of sources, models and images, and view the results using 3D visualization. 3D printing makes it not only possible, but also affordable.

All these are consolidated innovations on the market, but the research and innovation departments of manufacturers continue to investigate the potential of revolutionary technology for the automotive industry. There are designs and concept cars completely printed in 3D, such as the EDAG Light Cocoon, Stati of Local Motors (consisting of only 50 parts printed in less than 24 hours) or the LSEV of the Italian company XEV (electric, with 57 components, weighing only 450 kg).

At the State University of Sacramento, there is an autonomous Olli bus, almost completely printed in 3D, with a capacity of eight passengers, which develops a speed of 40 km/h and a travel distance of more than 160 km.

Being a global supplier for the automotive industry, Knauf Industries Automotive adapts its production processes to the needs of the industry. That is why we created the innovative IDLab laboratory, which uses the latest technologies to find the best solutions for our clients, including printing 3D models.

If you are interested in this information, then follow the link https://solidbrain.net/industries/automotive.